MS3900 SeriesMP3900

Chassis Mount Type

Connector Cover

Chassis Mount Type Signal Conditioners with Isolated Dual Output

The MS3900 Series is a line of signal conditioners developed by a new design concept. The series is designed to improve accuracy and stability while maintaining the primary features of the bestselling MS2900 Series, offering a 7-year warranty, the longest in the industry.

*1 Products are warranted for years from the date of shipment.

*2 Only the models MS397□.

| Warranty Period *1 | 7Years |

|---|---|

| Standard Lead Time | 6Days |

| Connection *2 | Programmable |

| Warranty Period *1 | 7Years |

|---|---|

| Standard Lead Time | 6Days |

| Power Supply | Rating: 100-240V AC / 24V DC |

| Connection | Chassis mounting |

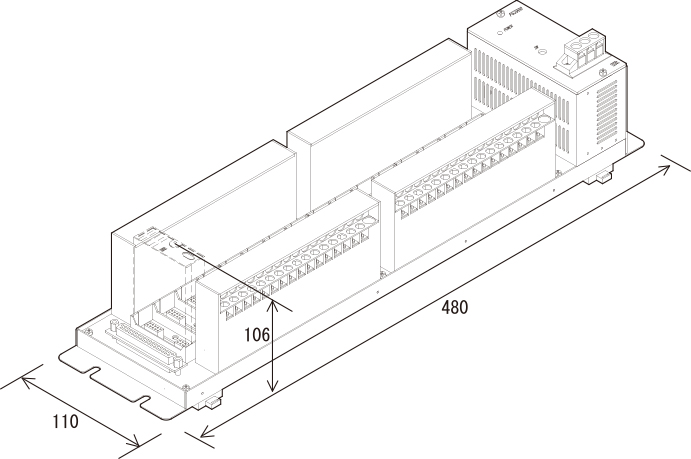

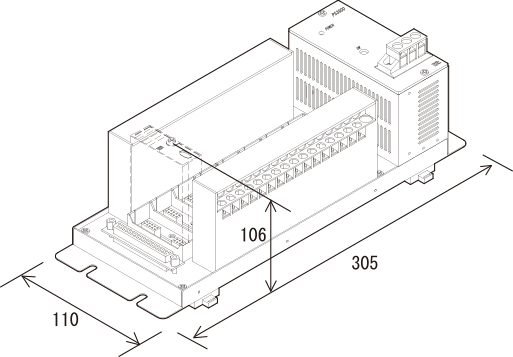

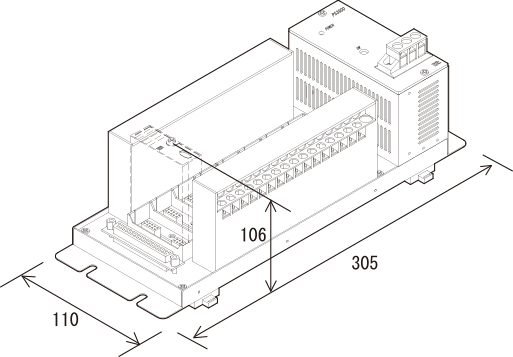

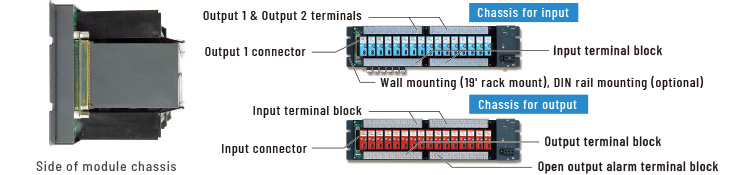

Chassis for input and output are separated completely from each other to prevent any accident caused by improper wiring. The terminal blocks are located above the chassis installation position, which helps make the wiring work easier and more efficient. The terminal blocks provide connections for all of the input, output 1 and output 2 terminals. The output 1 is connected in parallel to a 37-pin D-subminiature connector.

Coating is not only resistant to accidental exposure to corrosive gas or oily smoke, but has a number of benefits contributing to long-term reliability. It avoids direct exposure to air to protect printed circuit boards and electronic parts against humidity, moisture, dust, chemicals, and thermal stress, thereby preventing corrosion, migration and any other damages. (HumiSeal® 1A27NSLU is used as a conformal coating. )

The chassis employs drop-proof screws, thereby eliminating the need to care about dropping them during the wiring work. Besides, the M3.5 screws are one size larger than those for competitive products of the same grade, which makes field wiring much easier. Each terminal block cover is marked with terminal numbers on both sides to prevent improper connections.

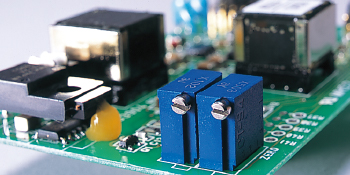

This series employs multi-turn trimmers for zero and span adjustments. Our conventional series have used 3-turn or 4-turn trimmers, but the multi-turn trimmers employed facilitate fine adjustment and provide improved resistance to vibration. The new trimmers also have static protection.

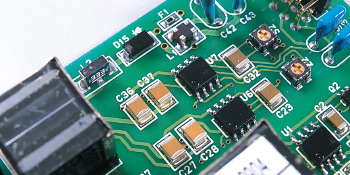

The MS3000 Series employs ceramic capacitors to achieve low current draw with extremely low heat generation, thus leading to long service life.

(The ceramic capacitors are not affected by prolonged use, as opposed to aluminum electrolytic capacitors.)

The unit uses an EMI filter in the DC power input section to remove high frequency noise. It is also immune to high RFI levels. Additionally, the output section includes an open circuit detection function for current output to provide an open output alarm to external devices (open collector output). The module can be easily live-swapped along the guide.

To achieve high reliability and durability, the contact parts of the main unit and socket are plated with gold of 0.2 μm in thickness. This prevents not simply wear caused by insertion and removal of the unit, but contact degradation even in harsh environments to ensure high reliability for a long period. Additionally, the module has its pins inside the connector to protect them from any damage to the pins during insertion or removal.

The 3907 distributor has a transmitter power supply switch on its front panel. Turning this switch off allows the distributor to be used as an isolator for adjustment. If you have not yet decided whether to use a distributor or an isolator at the design phase, you should select this model so that it can be used for both applications.

| Materials | Main Unit | ABS resin (UL 94V-0) |

|---|---|---|

| PCB | Glass fabric epoxy resin (FR-4: UL 94V-0) | |

| Conformal Coating | HumiSeal® 1A27NS (Polyurethane) | |

| Isolation | 4-way isolation between input, output 1, output 2, and power. | |

| Insulation Resistance | 100Ω min. (@ 500V DC) between input, output 1, output 2, power, and ground. | |

| Dielectric Strength | 1500V AC for 1 minute between input, output 1, output 2, power, and ground. | |

| Power Requirements | Via chassis |

|---|---|

| Overcurrent Protection | 300 mA fuse |

| Operating Temperature Range | -5 to 55℃ |

|---|---|

| Operating Humidity Range | 5 to 90% RH (no condensing) |

| Storage Temperature Range | -10 to 60℃ |

| Installation | Chassis mounting |

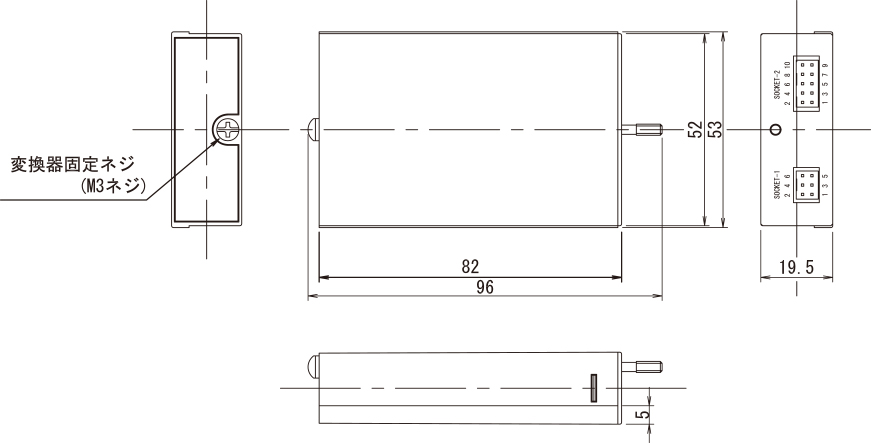

| Dimensions | W19.5 × H53 × D84 mm |

| Weight | 80g max. |